Overhead Cranes:

Industrial cranes used for heavy-duty applications in factories, warehouses, and other industrial environments. They run on fixed runways overhead.

Industrial cranes used for heavy-duty applications in factories, warehouses, and other industrial environments. They run on fixed runways overhead.

Single Girder Bridge Crane:

These cranes are efficient for handling materials weighing up to 16 tons and have a reach of up to 39 meters. They are suitable for operations in halls with lower ceiling heights and their compact design allows for maximum utilization of available heights. ZARRIN MEHR offers a variety of connection types to link the girder to the end-carriage, adapting to different building specifications.

Under Running Single Girder Overhead Crane:

Designed for challenging and limited spaces, these cranes move under the roof beam. They are designed for small dimensions with customized fittings on the main beam and excellent hook accessibility, allowing for maximum utilization of the building’s width. These cranes typically have a capacity of up to 8 tons and spans up to 25 meters, but custom designs with unlimited capacity are also available.

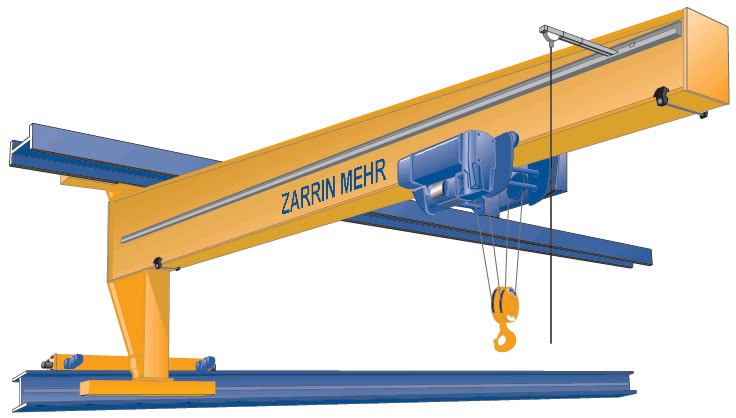

Wall Mounted Single Girder Overhead Crane:

These cranes operate on a distinct path and lower level compared to overhead cranes. They enable the transportation of loads in isolated production areas and allow for independent movements outside the scope of larger roof cranes. ZARRIN MEHR’s single girder wall travelling cranes have a capacity of up to 5 tons and a range of 12 meters.

Double Girder Overhead Crane:

For heavier loads of up to 120 tons, the double girder overhead crane is the preferred choice. These cranes are compatible with both old and new constructions, offering continuous operation, flexibility, and ease of use. They are available with a range of up to 40 meters and can be customized to meet specific requirements.

These cranes are similar to overhead cranes, but they run on a track at the ground level. They are often used in outdoor applications like shipyards, rail yards, or other industrial areas.

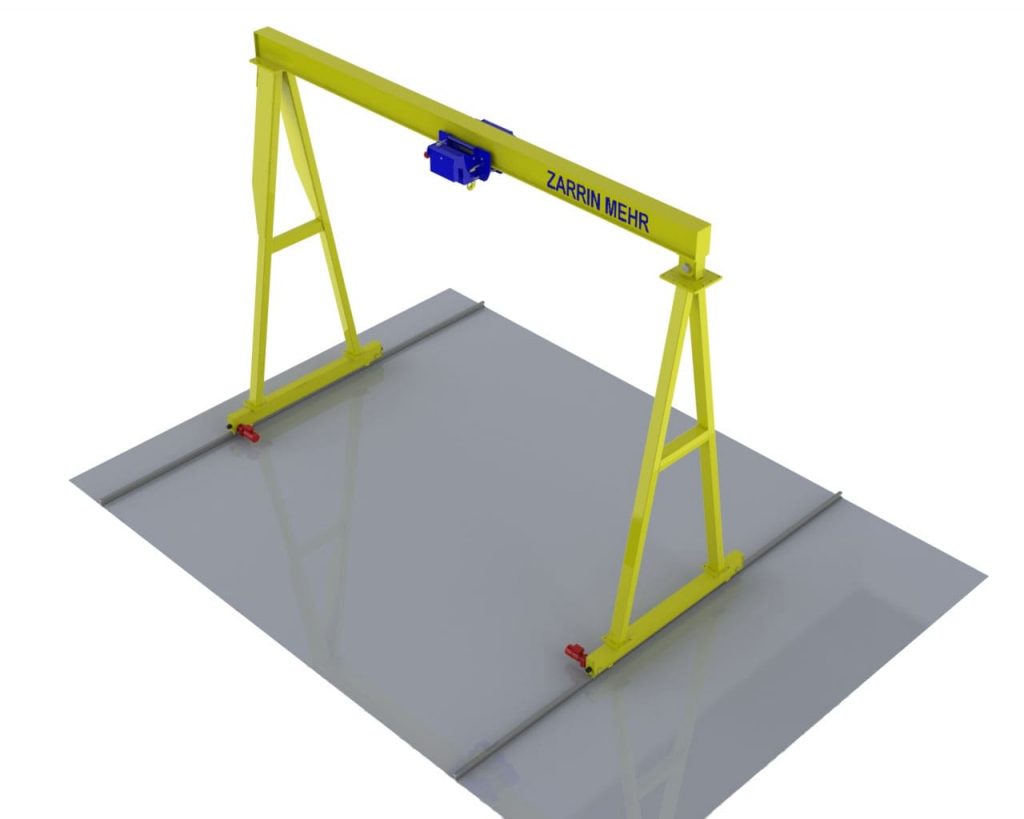

Single Girder Gantry Crane:

This crane type is designed to handle materials weighing up to 16 tons, with a span of up to 39 meters. Ideal for outdoor transportation, these cranes have a significant cost advantage as they don’t require a new building or an industrial shed for installation. Single girder gantry cranes move on a floor-surface path, distinguishing them from overhead cranes.

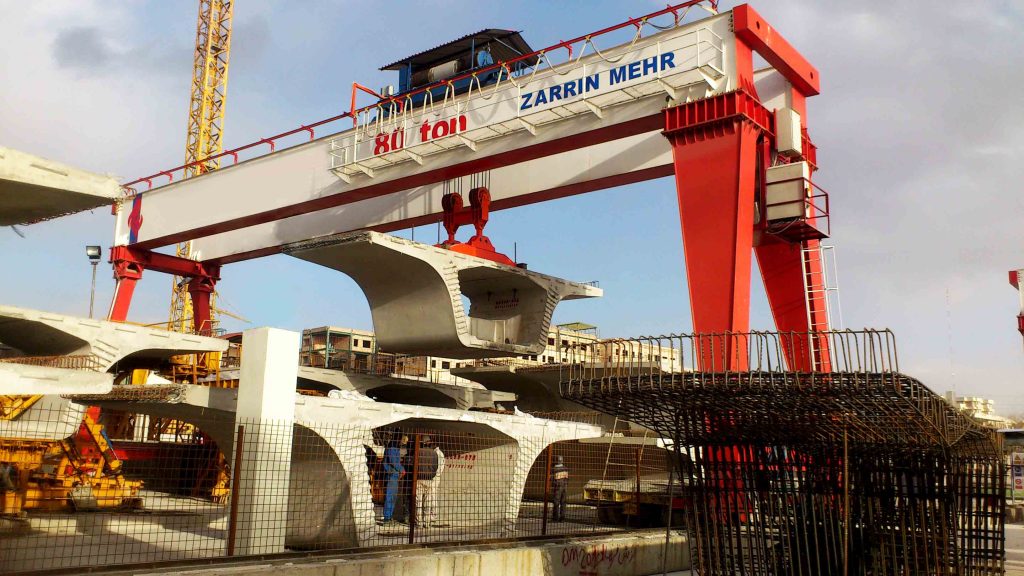

Double Girder Gantry Crane:

These are versatile cranes suitable for various indoor and outdoor applications and are particularly ideal for handling heavy loads. ZARRIN MEHR offers a variety of models, including those equipped with cabins, auxiliary hoists, and rotary crabs. The company also offers a 2-year warranty and 10-year after-sales service for these cranes, along with several features for enhanced safety and operation, such as weight indicators, safety sensors, movement limit switches, and a wind safety system for outdoor operation.

Single Girder Semi-gantry Crane:

These cranes are designed to handle materials up to 16 tons, ideal for both indoor and outdoor applications. They are distinguished by an inverted L-shape design, with one side mounted on upper-level runway rails and the other on ground-level rails, which is particularly suitable when a cabin component is required.

Double Girder Semi-gantry Crane:

These cranes can handle heavy loads of up to 120 tons and are ideal for extensive operational areas. They provide continuous operation, flexibility, and user-friendliness. ZARRIN MEHR uses computer programs to optimize the girder and end-carriage sections, resulting in reduced dead weight, increased durability, and cost savings.

These cranes have a horizontal member (the jib or boom), a movable hoist running along the jib, and are used in industrial premises.

Wall-Mounted Jib Crane:

This type of jib crane is typically mounted to the wall of a factory building or a suitable pillar within the factory. It has a rotation range of 180° and is mainly used for loading and unloading machinery. The pillar or wall to which the crane is attached must have appropriate dimensions to support the forces applied by the crane.

Pillar Mounted Jib Crane:

Pillar jib cranes are installed on a standalone pillar and are an ideal solution if your factory lacks a wall or column for crane assembly. They offer a rotation range of either 270° or 360°. ZARRIN MEHR can provide a suitable column for crane installation, and the crane can be anchored into a pit in the foundation or mounted on a concrete flange. The movements can be operated manually or electrically, and if the pillar jib crane is galvanized, it’s suitable for outdoor use.

Articulating Jib Cranes:

Articulating jib cranes are a special type of jib cranes designed to provide additional flexibility and maneuverability in material handling. They have two separate swing arms (the “articulating” aspect) connected by a pivoting joint, allowing the crane to bend, or “articulate” along its length. This design allows the crane to reach around obstacles and into hard-to-reach areas, such as machinery or building structures that may obstruct the path of a traditional, straight-arm jib crane.

Hoists are lifting devices used in conjunction with cranes to lift, lower and move loads.

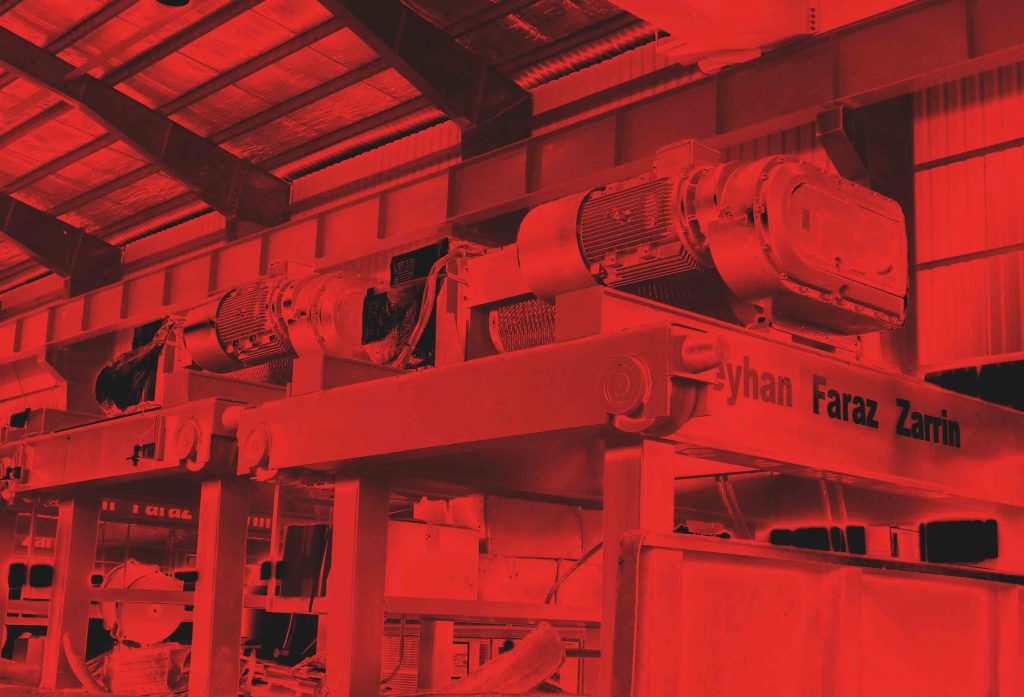

ZMH Series Wire Rope Hoists:

The ZMH series are modular wire rope hoists, designed to be flexible and adaptable for a wide range of applications. The ZMH-LH variant is particularly suitable for situations with limited height, able to handle loads between 1 and 16 tons. This series offers an economical choice for many standard material flow applications. The carriage can be adjusted to fit the width of different girder flanges.

ZH Series Wire Rope Hoists:

The ZH series is versatile, functioning as a mobile hoist in overhead and gantry cranes, mono-rails, or as a fixed winch. They are reliable and durable, designed to perform in high temperature, dust, and humidity environments. The ZH-KFZ variant is best suited for double bridge overhead cranes, used for high load capacities and long hook paths, with capacities ranging from 6.3 to 25 tons.

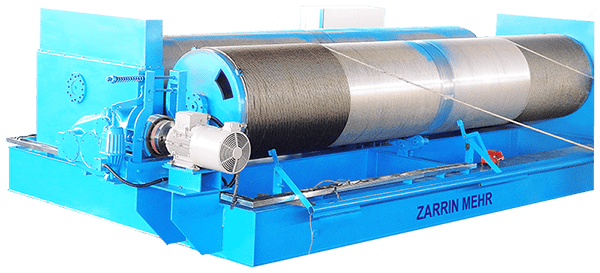

ZOW Series Wire Rope Hoists:

Designed for special projects that require heavy material handling, unusual hook height, and high working group, the ZOW series can handle loads between 8 and 120 tons. The carriage of this series is powered by a two-stage gearbox. There’s also the ZOW-LH version for situations with limited ceiling height.

ZPOW Series Open Winches:

Also known as a wire rope or lifting winch, the ZPOW series is designed for specific projects and can perform heavy duty tasks efficiently. The speed of the hook adjusts automatically depending on the load. This series is widely used in various industries including construction, water protection, forestry, mining, and harbors for loading or unloading heavy loads.

These are all specialized lifting devices designed for handling specific types of loads.

Hook Block:

The ZARRIN MEHR hook blocks are designed to the latest FEM1001 and DIN15020 standards, which ensure safety and durability. They are made from high-grade forged steel and are fitted with safety guards to prevent chain escape. They feature pulleys that are attached to the main shaft by double roller cylindrical ball bearings. The careful design of the groove’s throat prolongs the wire rope’s lifetime.

Lifting Beam:

Lifting beams are used to secure and support loads during lifting. These beams maintain wire ropes at approximately a 90-degree angle, preventing damage to the load and crane hardware, as well as preventing slippage of wire ropes attached to the load. ZARRIN MEHR offers consultation services to increase safety with under-hook loading devices.

Coil Lifting Equipment:

ZARRIN MEHR’s C-Hooks provide a safe, efficient solution for handling coils. They are made from a single piece of alloy steel and are designed for high working group operations and harsh conditions.

Roll Lifting Equipment:

The roll lifting beam is designed to move and handle rolls using the roll shaft. It’s an efficient solution for roll handling, especially in cases with height limitations. ZARRIN MEHR’s roll handling equipment is designed according to the latest standards like ASME B30.20 & BTH-1, ensuring safety and efficiency.

Elevate the efficiency of your operations with our high-performance products. Reach out to our dedicated team for more detailed information