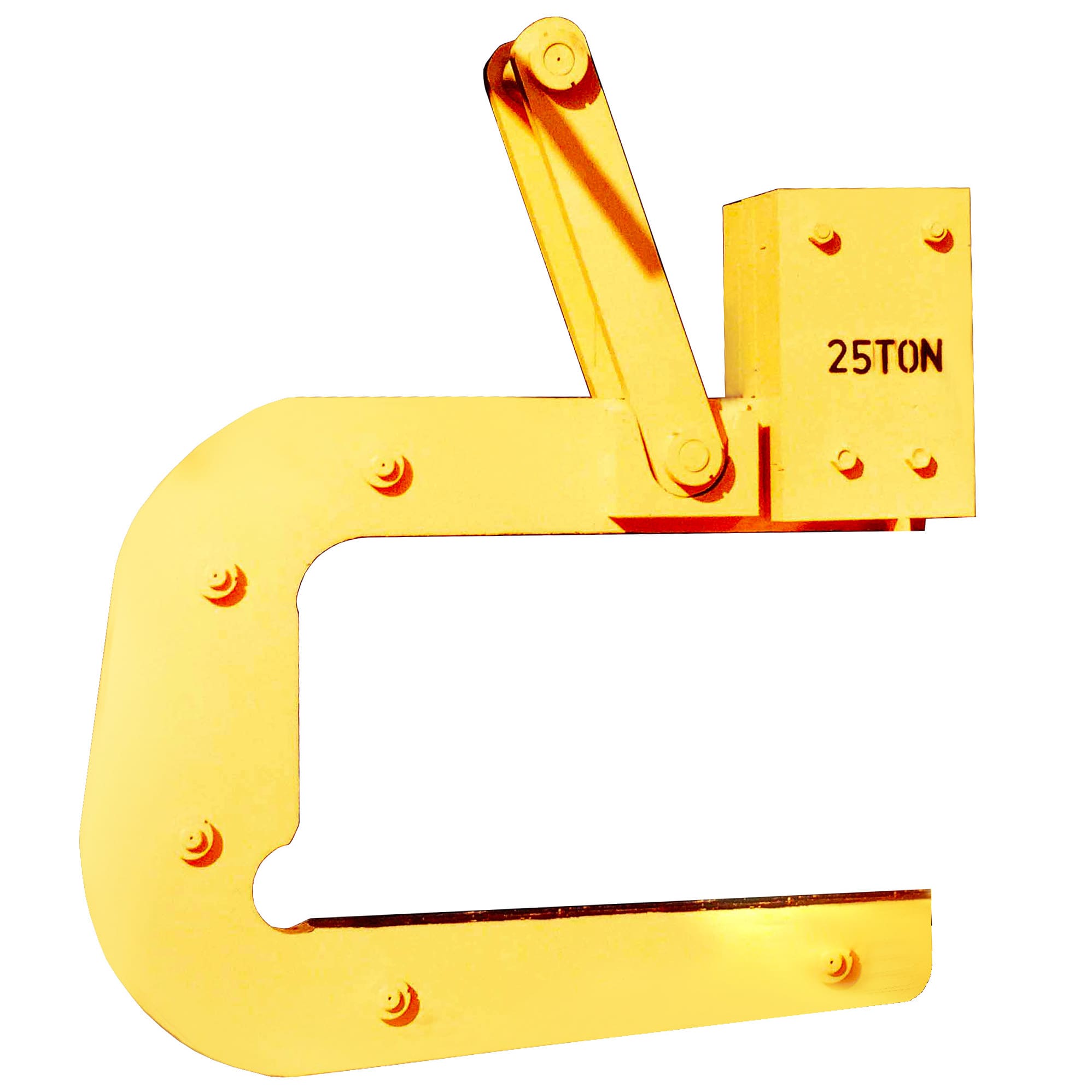

Hook block:

The new ZARRIN MEHR hook blocks are designed according to the latest requirements and techniques of the FEM1001 and DIN15020 standards. Safety in the event of failure in all cases is greater than that recommended by FEM standards. The pendant parts (hooks, cross-axels, nuts) are in accordance with DIN15411 and hooks are designed in accordance with DIN15401,15402 and are made of forged grade steel (StE355 (class P, DIN 15400). Of course, the class S, T and V They are also custom-made. To prevent chain escape, all hooks are equipped with safety guards.

The pulleys are designed and constructed in accordance with the relevant standards by ZARRIN MEHR Engineering Co., and are connected to the main shaft by double roller cylindrical ball bearings, due to the lubrication a lubricating nipple created at the bottom of the main shaft . At the time of the construction of the sheaves, special attention is paid to the throat of the groove.

The definition of the radius of the groove in accordance with the standard (DIN 15601 (r = 0.525 d)) increases the lifetime of the wire rope considerably, and if the wire rope is properly fitted to the pulley’s throat, its lifetime will increase to the maximum state . The rollers that are hardened by thermal stress will increase the lifespan of the steel rope and will be made by customers order. The distance between the pulleys and other components of the hook block is very low due to the selection of the bearings, which leads to a reduction in the size of the hook block.

[ult_animation_block animation=”InfinitePulse” animation_duration=”1″ animation_delay=”1″ animation_iteration_count=”1″]