The weight and size limits for a gantry crane can vary significantly depending on its design, materials, and intended use. Here are some general guidelines:

Weight Capacity:

- Light-Duty Cranes: These can handle loads from a few hundred pounds up to around 5 tons. They are often used in auto repair shops, small workshops, or light assembly lines.

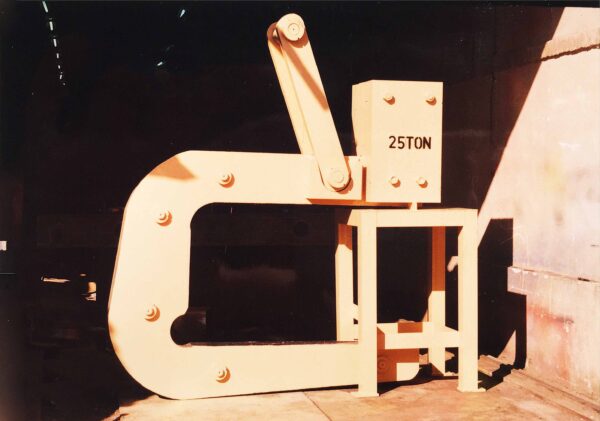

- Medium-Duty Cranes: These are generally designed to handle weights between 5 and 20 tons. They are commonly used in manufacturing and general industry.

- Heavy-Duty Cranes: These cranes can handle very high capacities, often up to several hundred tons. These are used in shipyards, heavy manufacturing, and construction of large structures like bridges and skyscrapers.

- Specialized Cranes: Some cranes are specially designed for even greater loads, such as those used in shipbuilding, where they may lift sections of a ship that weigh thousands of tons.

Size Limits:

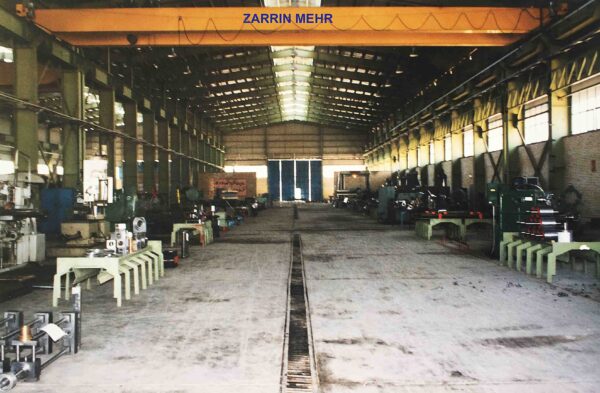

- Span: This refers to the length of the horizontal girder, which can range from a few feet for small workshop cranes to over a hundred feet for industrial cranes.

- Height: The height of the crane is determined by the length of its legs, which can also vary significantly. Some cranes offer adjustable heights.

- Reach: Some gantry cranes come with telescopic booms to extend their reach horizontally.

Important Considerations:

- Floor Space: The available floor space may limit the size of the gantry crane you can accommodate.

- Headroom: The vertical space in the facility can also be a limiting factor, especially for top-running cranes.

- Operational Clearance: Adequate space is needed not just for the crane but also for its operation, including room for the load being lifted, the operator, and any other equipment or personnel in the area.

- Portability: Some smaller gantry cranes are designed to be easily disassembled and transported.

When considering a gantry crane, it’s crucial to understand your specific weight and size requirements, as exceeding the crane’s limitations can result in failure and pose serious safety risks. Always refer to the manufacturer’s specifications and consult with engineers or other experts to determine the right crane for your needs.

Certainly, let’s dive deeper into the considerations around weight and size limits for gantry cranes, focusing on the factors that influence these limits and why they’re essential.

Factors Influencing Weight Capacity:

- Material: The material of the gantry crane plays a significant role in determining its weight capacity. Steel cranes generally offer higher strength, but aluminum cranes can be adequate for lighter loads and offer the advantage of being more portable.

- Design: The structural design, including whether it’s a single-girder or double-girder crane, affects the weight it can bear. Double-girder cranes typically have higher weight capacities.

- Hoist: The type and capacity of the hoist also affect the overall weight limit. A chain hoist might be used for rougher, heavier tasks, whereas a wire rope hoist might be used for tasks requiring more finesse.

- Engineering Safety Margins: The crane’s design will include safety margins, ensuring that it can handle more than the maximum stated load to account for factors like swinging or sudden movements.

Factors Influencing Size Limits:

- Workspace Dimensions: The available area in the workspace determines the maximum size of the gantry crane, both in terms of height and span. Ensure there’s enough operational clearance around the crane.

- Task Requirements: The dimensions of the objects to be lifted and moved will influence the span and height you’ll need. For example, if you’re lifting something tall, ensure the crane’s maximum height can accommodate it.

- Mobility Needs: If the crane needs to be moved around, its dimensions should align with doorways, corridors, or any other spaces it will need to pass through.

Why Weight and Size Limits are Important:

- Safety: Exceeding the weight or size limits can be extremely hazardous, potentially causing mechanical failure or even collapse, putting personnel at risk.

- Operational Efficiency: Selecting a crane with the appropriate weight and size limits for your needs ensures that tasks are completed efficiently. An undersized crane can slow down operations, while an oversized one could be a wasteful expenditure.

- Longevity: Consistently operating the crane near or beyond its limits can result in faster wear and tear, reducing its operational lifespan.

- Compliance: Overloading a crane can result in violations of workplace safety regulations, leading to fines or legal repercussions.

- Cost: Knowing your exact requirements can save you money. Oversizing can result in unnecessary capital expenditure, while undersizing can lead to operational inefficiencies and potential upgrade costs.

- Accessibility: Cranes that are too large for the available space can create issues with site accessibility, potentially hindering other operations or requiring costly modifications to the existing infrastructure.

When considering a gantry crane, it’s vital to carry out a comprehensive needs assessment, possibly involving engineers or lifting experts to ensure that you select a crane that not only fits within your physical space but also meets your lifting requirements in terms of weight and size.