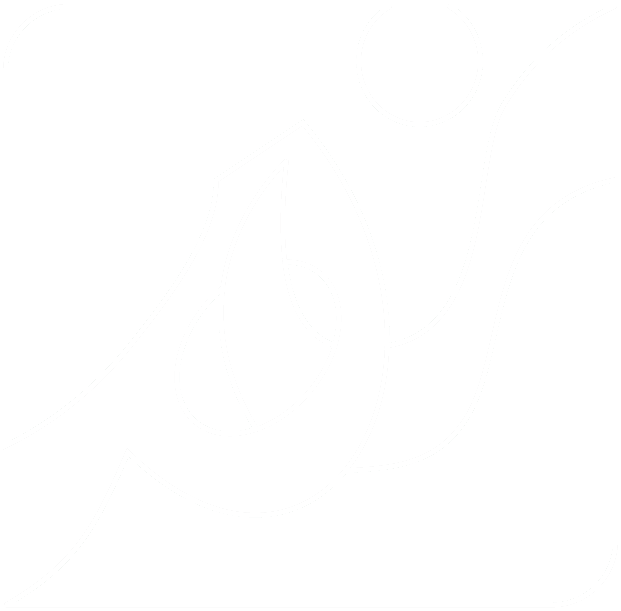

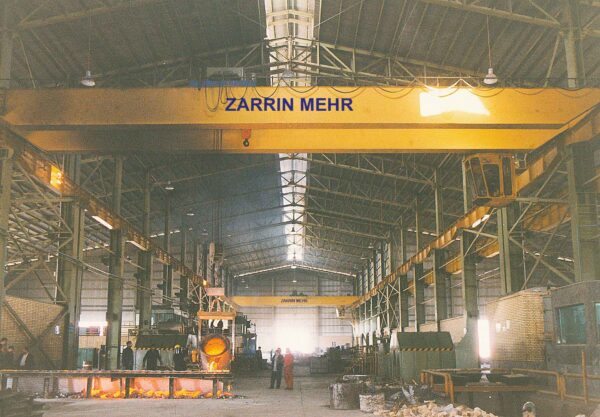

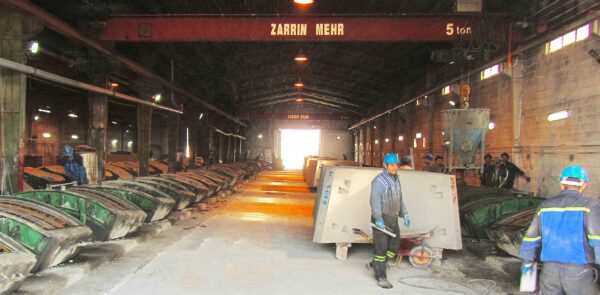

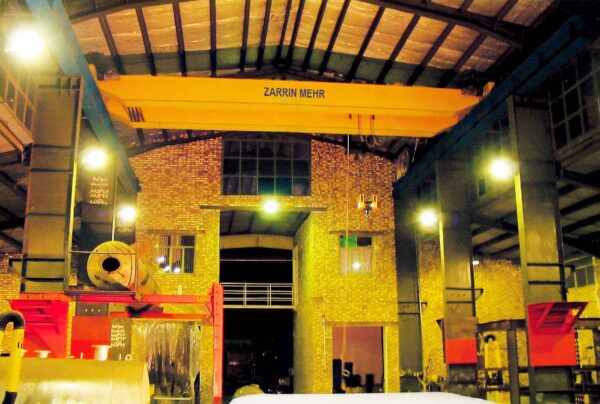

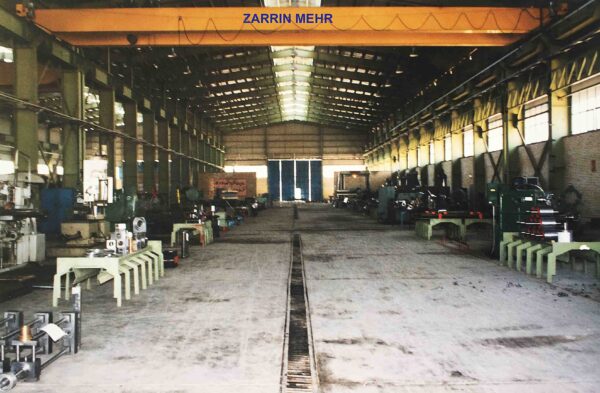

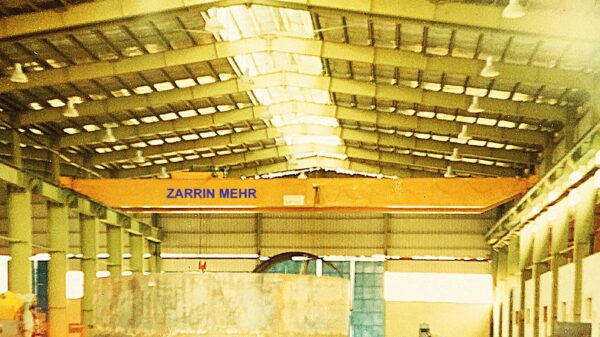

A bridge crane, also commonly known as an overhead crane, is a type of crane used for lifting and transporting heavy materials in an industrial setting. The crane consists of a bridge beam that spans the area where lifting is needed. This bridge beam is mounted on parallel runways, which are usually attached to the walls or structural supports of the building. A hoist, the lifting component, travels along this bridge to lift, move, and lower loads.

Components of a Bridge Crane:

- Bridge: This is the main horizontal beam that spans the length of the room or designated area. The hoist and trolley are mounted on this bridge.

- Runways: These are the parallel beams or rails installed on either side of the area where lifting is required. The bridge moves along these runways.

- Hoist: This is the unit that performs the actual lifting and lowering of the material. It’s usually electrically powered and is mounted on a trolley for lateral movement.

- Trolley: This is the mechanism that holds the hoist and moves it along the length of the bridge, allowing the hoist to be positioned over the load.

- End Trucks: These are structural elements that contain wheels and allow the bridge to travel along the runways.

- Control Station: This could be a wired pendant, a fixed control panel, or even a wireless remote, allowing the operator to control the crane’s movements.

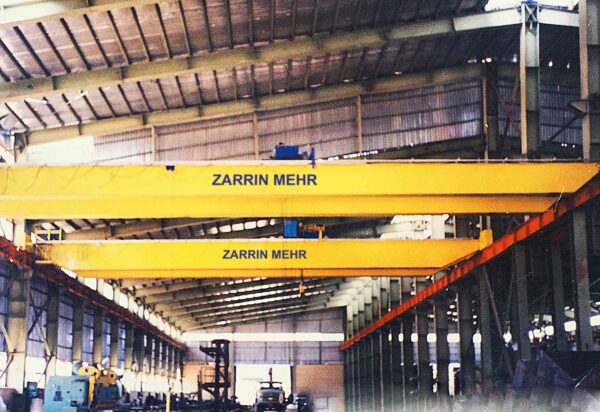

Types of Bridge Cranes:

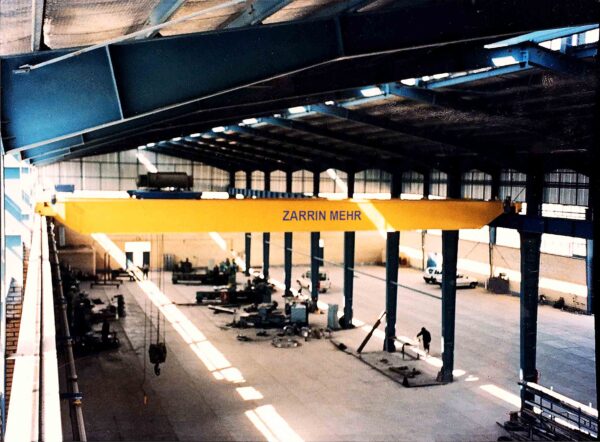

- Top Running Cranes: These have the bridge riding on top of the runways. Generally used for heavy-duty applications, they can accommodate higher lifting heights.

- Under Running (or Underhung) Cranes: These have the bridge hanging from the runways, which are usually suspended from the roof of the building. They are generally used for lighter loads and offer the advantage of maximizing the available headroom in a facility.

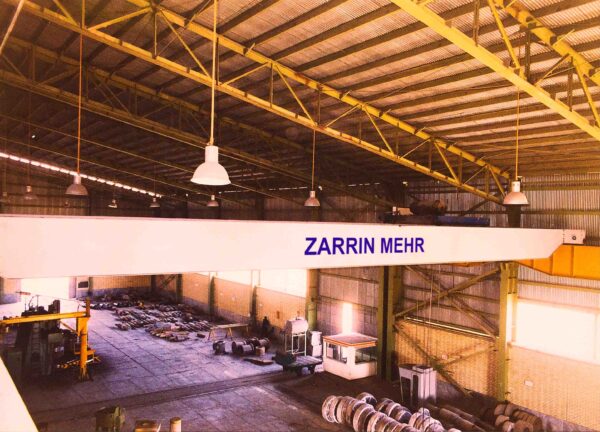

- Single Girder Cranes: These have one main bridge beam. They are generally used for lighter loads and shorter spans.

- Double Girder Cranes: These have two parallel bridge beams. These are more robust and can handle heavier loads and longer spans.

Advantages:

- Efficient Movement: Allows for the quick and efficient transport of heavy materials horizontally and vertically.

- Space Utilization: Being overhead, these cranes free up floor space for other uses.

- Safety: When properly operated and maintained, they can be a safer option for moving heavy loads compared to forklifts or manual labor.

Safety Precautions:

- Routine inspection and maintenance are essential for the safe operation of bridge cranes.

- Operators should be adequately trained and certified.

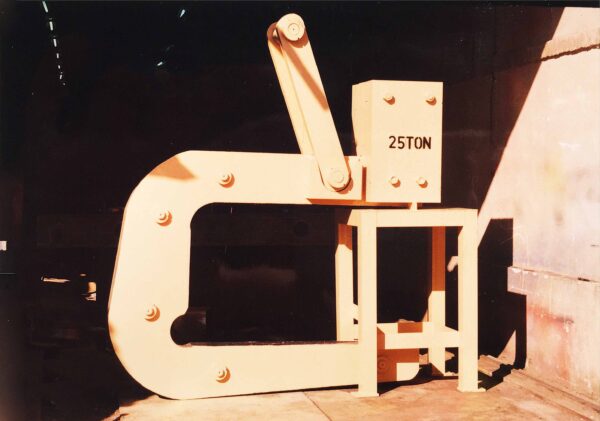

- Always check that the crane is rated for the load you intend to lift.

Bridge cranes are an essential component of many manufacturing and storage facilities, helping to improve efficiency and safety in the handling of heavy or bulky materials.