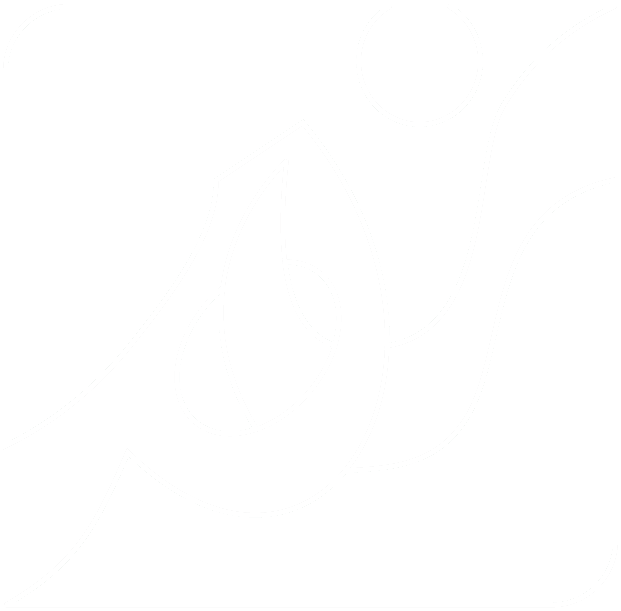

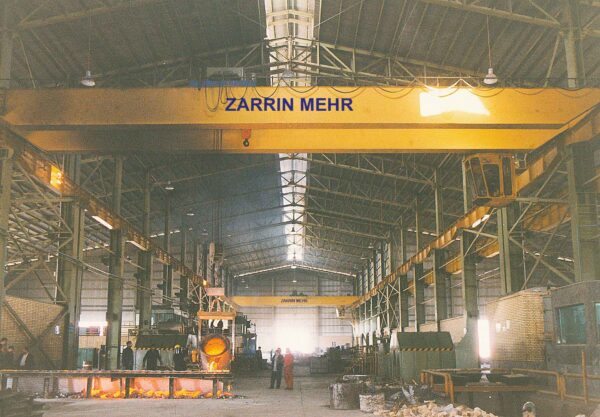

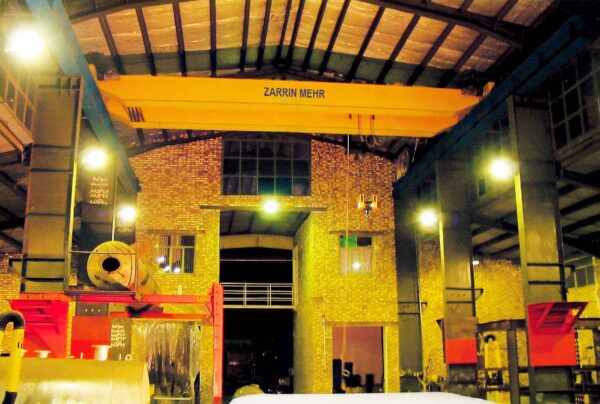

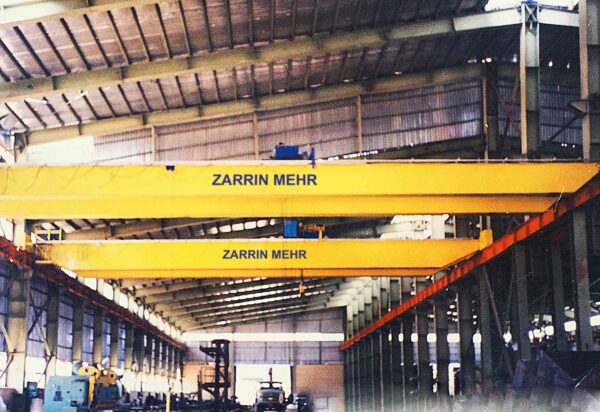

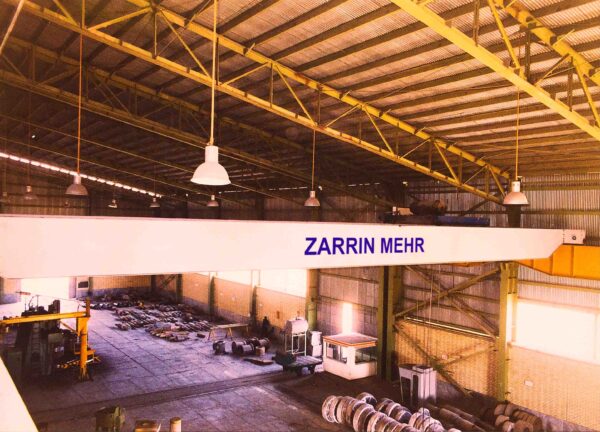

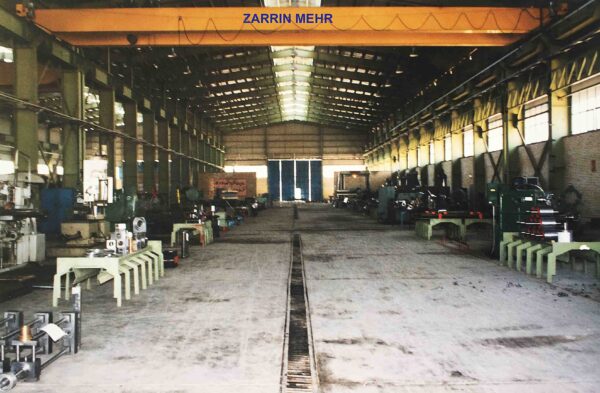

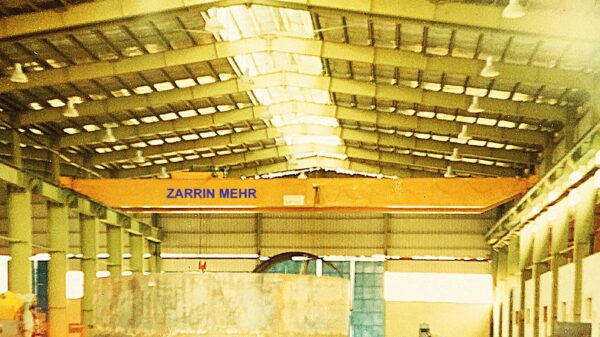

Material Handling in Manufacturing:

In manufacturing facilities, gantry cranes are often used to transport raw materials from storage areas to the production line. They are crucial in assembly lines where heavy parts may need to be moved or positioned precisely.

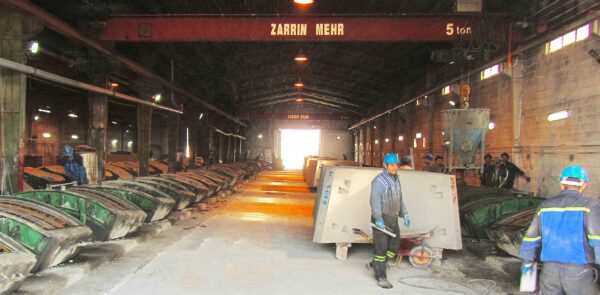

Shipping and Logistics:

In ports and intermodal facilities, heavy-duty gantry cranes are often used for lifting containers off ships and onto trucks or trains. These cranes can be extremely large and powerful, designed to lift several tons.

Construction:

In construction settings, gantry cranes can be used for various tasks, including moving large prefabricated parts like steel beams, concrete sections, and even entire modular buildings. Their utility can be especially high in tight urban environments where space is at a premium.

Automotive Industry:

In the automotive sector, smaller, more specialized gantry cranes are often used. These cranes are frequently employed to lift heavy components like engines or transmissions into place during the assembly process.

Scrap Yards:

Gantry cranes in scrap yards often come with specialized attachments like electromagnets or grapples to handle a wide variety of materials, from scrap metal to decommissioned vehicles.

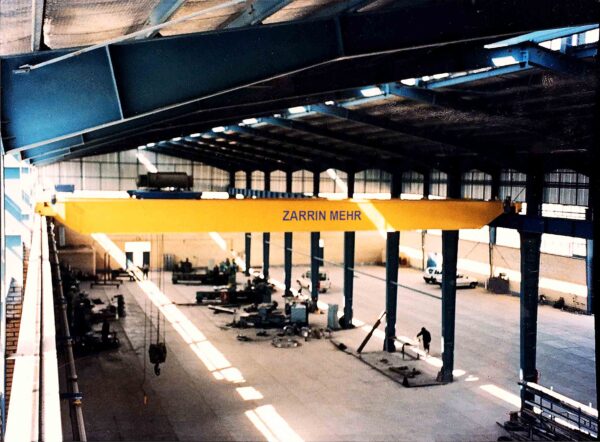

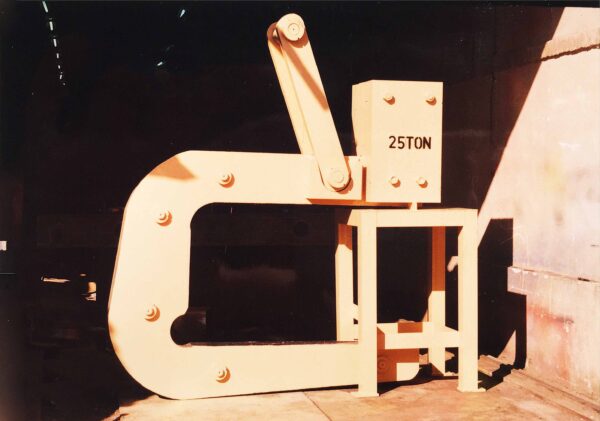

Maintenance and Repair:

In repair shops or industrial maintenance settings, gantry cranes can lift heavy machinery or parts, enabling easier access for repairs. These cranes can be particularly useful in settings like railway depots, where locomotive components may need to be lifted for maintenance.

Aviation:

In the aviation sector, specialized gantry cranes are often used for the precise and delicate task of lifting jet engines, wings, or other large and sensitive components during both the manufacturing and maintenance processes.

Small Workshops:

In smaller settings like auto repair shops, portable gantry cranes can be useful for engine removals or installing heavy components. These are usually smaller, more compact, and sometimes even foldable for easy storage.

Customization Options:

- Adjustable Height: Some gantry cranes come with adjustable heights to accommodate different lifting needs.

- Telescopic Booms: Certain applications may require an extendable boom for extra reach.

- Variable Speed Control: Depending on the precision required, some gantry cranes offer variable speed controls for both the trolley and the hoist.

- Type of Hoist: The hoist can often be customized based on lifting needs, with options like chain hoists for rough environments or wire rope hoists for more delicate lifting.

- Power Source: Options often include manual, electric, or pneumatic, depending on the application and environment.

- Material: Cranes can be made from different materials like steel for heavy-duty applications or aluminum for lighter, more portable needs.

- Safety Features: Overload alarms, emergency stops, and anti-collision devices are some of the safety features that can be added.

By understanding the specific needs of an operation, one can choose the appropriate type of gantry crane and customize it for optimal performance and safety.